Technologies

Investing to Grow

With over 100 CNC machines, GCM has a wide and focused range of precision manufacturing equipment to meet customer needs. We continue to invest to scale production for our key strategic partners and add the latest technology.

5-Axis Milling

GCM is equipped with 5-axis machining technology at each of our global sites. Our 5-axis platforms range from 22x22x12 inches and 18,000 RPM to 6x6x8 inches and 50,000 RPM. With more than eight machines, GCM can meet the most demanding 5-axis requirements.

Vertical and 4-Axis Milling – Mazak 510, Brother, Haas

We have over 50 vertical mills across all sites. All sites have 4-axis capability for complex milling applications.

Multi-Axis Mill/Turn Capabilities – Mazak Integrex i200, Multiple

For many applications turning equipment with live tooling allows for productive machining and the ability to hold critical tolerances. GCM has over 15 turning centers with turret or B-axis capability for your demanding production parts.

Screw Machine Technologies – Citizen L20

GCM has provided precision Swiss components for over 20 years to our customers. Tolerances on complex components as tight as +/- .0001 inch. Disciplined approach to in-run checking of quality to ensure conformance. Four Swiss style screw machines in total.

EDM – Makino Wire EDM

Our USA facilities are outfitted with the latest in Japanese technology for Wire EDM. Capacity up to 25x25x10 inches. Two machines in total.

Horizontal Milling – Mazak 6800 High-Speed Aluminum

Horizontal milling capabilities exist at both of our USA facilities, with 10 spindles overall. Systems include multi-pallet FMS automation for productive scheduling and quick response to demand. Largest size 66x66x60 inches. Both high-speed spindles for aluminum and high torque, low rpm for super alloys and steel.

Robotic Welding – Lincoln System 55 with Head Stock and Tail Stock

With over 15 years of robotic welding experience GCM is capable of handling complex weldments that incorporate precision features. Our two robotic welding systems are identical and provide consistent results. Our engineering team is experienced with weld validation requirements for AWS D 1.1 and D1.2. Weldments size up to 120″ and 6,000lbs.

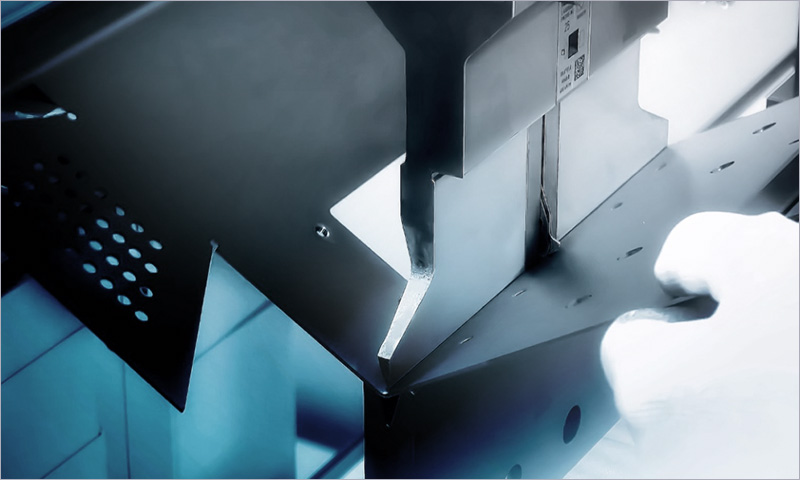

Laser/Punch Sheet Metal Processing – Trumpf Trumatic 7000 (or 6000)

Our sheet metal operations include state-of-the-art laser/punch technology from Trumpf. This equipment is fully automated and provides for rapid processing of small to large quantity runs with minimal custom tooling. Specialized embossed features possible with our active die technology.

Press Brake Technology – Trumpf 5320

Precision-cut flat sheets can be bent to form complex geometries for a variety of specialized product applications.

Hydrogen Brazing/Soldering – Camco J12 Furnace, Soldering Iron

GCM provides customers with specialty hydrogen brazing and IPC soldering for medical devices.

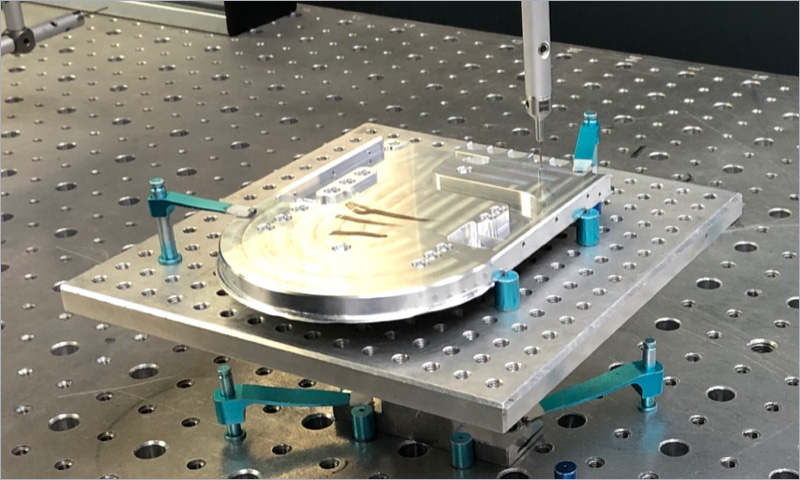

Metrology Technology – Zeiss Contura G2, Mitotoyo, Keyence Vision Systems

GCM has 17 CMMs, 14 of which are Zeiss Contura G2s. With the same CMM at each facility we are able to share inspection resources across the company for programming. We qualify products at multiple sites when appropriate and can duplicate validations to ensure consistency of quality.